Micrographs

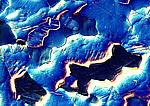

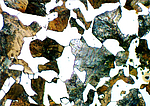

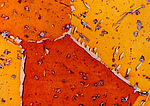

Image 1: technical zinc

- component/application: galvanizing

- material: technical zinc

- structure: zinc crystals

- structural features: acicular twins

- phases: zinc

- objective: 5x/0,13

- magnification: 50x

- lighting technology: Nomarski interference contrast

- etching method: 1% alcoholic nitric acid

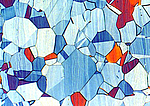

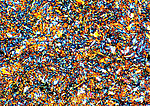

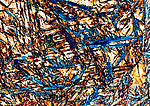

Image 2: X10CrNi18-8

- component/application: antenna wire

- material: X10CrNi18-8

- heat treatment: solution-annealed

- structure: austenite

- structural features: parallel twin boundaries

- phases: γ-Fe

- objective: 20x/0,4

- magnification: 200x

- lighting technology: bright field

- etching method: Bloech and Wedl I

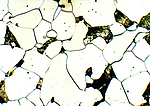

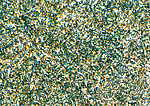

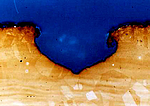

Image 3: C15

- component/application: gear wheel

- material: C15

- heat treatment: normalized

- structure: ferrite, pearlite

- phases: α-Fe, α-Fe + Fe3C

- objective: 50x/0,7

- magnification: 500x

- lighting technology: bright field

- etching method: Nital

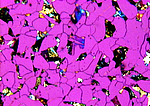

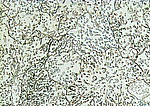

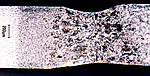

Image 4: C35

- component/application: clutch component

- material: C35

- heat treatment: normalized

- structure: ferrite, pearlite

- phases: α-Fe, α-Fe + Fe3C

- objective: 50x/0,7

- magnification: 500x

- lighting technology: polarization

- etching method: Nital

Image 5: C45

- component/application: gear shaft

- material: C45

- heat treatment: normalized

- structure: ferrite, pearlite

- structural features: pearlite lamellas

- phases: α-Fe, α-Fe + Fe3C

- objective: 50x/0,7

- magnification: 500x

- lighting technology: bright field

- etching method: Nital

Image 6: C60

- component/application: practical course

- material: C60

- heat treatment: normalized

- structure: ferrite, pearlite

- phases: α-Fe, α-Fe + Fe3C

- objective: 50x/0,7

- magnification: 500x

- lighting technology: bright field

- etching method: Nital

Image 7: C60

- component/application: practical course

- material: C60

- heat treatment: oil quenching

- structure: martensite, bainite, pearlite, ferrite

- phases: α-Fe, α-Fe + Fe3C

- objective: 50x/0,7

- magnification: 500x

- lighting technology: bright field

- etching method: Nital

Image 8: C60

- component/application: practical course

- material: C60

- heat treatment: water quenching

- structure: martensite

- phases: α-Fe

- objective: 50x/0,7

- magnification: 500x

- lighting technology: bright field

- etching method: Nital

Image 9: C60

- component/application: practical course

- material: C60

- heat treatment: tempered

- structure: tempered martensite, carbides

- phases: α-Fe, FexC

- objective: 50x/0,7

- magnification: 500x

- lighting technology: bright field

- etching method: Nital

Image 10: C130

- component/application: piercing mandrel

- material: C130

- heat treatment: GKZ (annealed, consisting of spheroidal carbides)

- structure: ferrite, spheroidite

- phases: α-Fe, Fe3C

- objective: 100x/0,9

- magnification: 1000x

- lighting technology: bright field

- etching method: Nital

Image 11: C135

- material: C135

- heat treatment: normalized

- structure: pearlite + grain-boundary cementite

- objective: 50x/0,7

- etching method: Klemm I

Image 12: Brass

- material: special-purpose brass

- structure: yellow/red: ß'-brass, light gray: α-phase, dark gray: NiAl (starlike)

- objective: 50x/0,7

Image 13: X10CrNi18-8 and C15

Image 14: C130

- material: C130

- heat treatment: hardening (quenched from 930 °C)

- structure: martensite (colored needles), reatained austenite (bright spacings)

- objective: 50x/0,7

Image 15: Pure titanium (semi-deformed)

- material: pure titanium (semi-deformed)

- objective: 20x/0,4

- etching method: Weck

Image 16: Bronze

- material: Bronze

- structure: Cu-Sn solid solutions

- objective: 50x/0,7

- etching method: Klemm II

Image 17: X6CrNiMoTi17-12-2 (pitting corrosion)

- material: X6CrNiMoTi17-12-2 (pitting corrosion)

- structure: austenite

- objective: 20x/0,4

- etching method: Beraha II